The type of work, the type of materials used, the characteristics of the machinery, are such that there are numerous hazards with consequent risks to the safety and health of workers.

The most critical work departments can be summarised in 4 macro-areas:

- Melting area

- Forming area

- Casting area

- Finishing area

Each process has its own specific technical and environmental characteristics, with associated risks and dangers for the safety and health of users, which therefore require appropriate safety devices.

It is therefore necessary to carry out a thorough assessment, by professionals, to identify potential risk factors, which we can summarise in a few macro points:

- Risks related to the work environment and the task performed

- Risks related to the use of work equipment (electrical, mechanical)

- Risks related to the use of chemical products (fire, explosion, accidental contact)

- Risks related to third parties

As regards risks from contact with heat or molten metal splashes, we can mention certain activities in the production chain, such as the management of furnaces and castings, welding and thermal cutting tasks, electrical and mechanical maintenance and the transport of processed raw materials.

In addition, those involved in these tasks are often subject to uncomfortable working conditions with regard to microclimate and thermal stress.

What is meant by thermal stress?

We refer to ‘thermal stress’ when an operator is unable to keep his body temperature within limits compatible with his vital functions.

To understand what degree of thermal stress these categories of workers are subjected to, one only has to consider that many operators work in the proximity of incandescent melting pots that have a temperature of 800°C to 1500°C, depending on the molten metal.

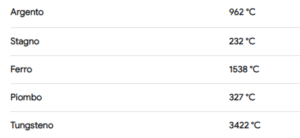

Some examples of melting temperatures:

In these environments, the continuous and forced effort of the organism to achieve a balance, combined with the subjective sensitivity of each individual, can lead to the development of real pathological processes if exposure is not limited in time or if the right safety measures are not put in place.

The right work clothing to counter thermal stress in foundries

At Coval, we want to highlight the importance of providing adequate PPE to workers to protect them from excess heat.

Personal protective equipment can be combined with integrated cooling systems or be designed with breathable materials to help prevent heat exhaustion and injury.

Anyone working in the land sector is aware of the absolute necessity of wearing aluminised safety equipment to safeguard their health in the workplace, such as jackets, trousers, aprons, coats.

Aluminised clothing serves to protect the worker from two types of risks that occur in foundry work and in the metal industry:

- Molten metal splashes: leading to burn injuries

- Radiant heat: which can lead to thermal stress

They are designed to be worn by the operator in the case of very hazardous operations, in addition to normal work clothing (intermediate protective layer). This is why their function is that of an absolutely necessary outer shell to ensure maximum protection from heat and accidental flames.

(For a more in-depth look at this topic, we suggest you read our article on how best to approach the choice of the right PPE, by clicking HERE).

New Prowear D3 E3 line: clothing for the metal industry

Jacket and trousers in an inherently flame-retardant fabric, for protection from molten metal, which does not lose its properties after washing, soft and comfortable.

The safest flame retardant clothing that cannot be missing from PPE for foundry, iron and aluminium production.

A high-end line that complies with ISO 11612:2015 A1 B1 C1 D3 E3 F1 for protective clothing against heat and flame.

Contact us to find out more.