For each PPE you wear, it is important to know the Reference Standard to be followed, so that you can be sure you have the right protection in the working environment.

It is therefore essential to know how to read the labels inside the garment, and the various markings, as they contain all the necessary information on the levels of protection provided.

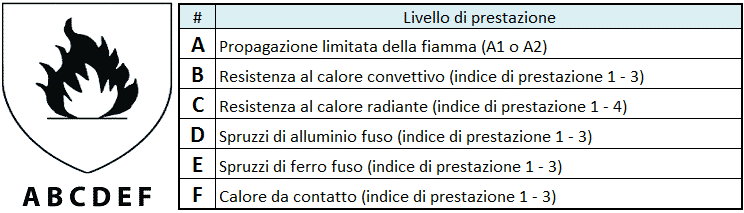

Workwear according to EN ISO 11612:2015

ISO 11612:2015 provides different test methods for the materials that make up the garment. Each of the tests corresponds to a letter from A to F and the level of resistance is indicated with a specific scale, different for each test.

A.Limited flame spread test

B.Convective heat resistance test

C.Radiant heat resistance test

D.Test for molten aluminium

E.Test for molten iron

F.Contact heat resistance test

NB: With the exception of hoods certified to EN ISO 11612, head, hand and similar protection products are not included in this standard.

Requirements for clothing EN ISO 11612:2015

To be recognised according to EN ISO 11612, workwear must have minimum performance levels on the first index A and on at least one of the other specified indices (B to F). Other requirements are also required:

- An overlap of at least 20 cm between jacket and trousers when standing

- No lapels on sleeves and trouser legs

- Fastenings must have a protective flap, have a distance of 15 cm between buttons and necklines must have a closure

- If trousers have a side slit down the leg, they must be foldable and have a flap

Application of the standard: which working environments?

Here are some areas where the standard is applied:

Welding

- Foundry industry (iron, steel, aluminium)

- Heavy industry and Maintenance

- Refinery

Coval Safety and compliance with regulations: High-end PPE

An essential principle at Coval Safety is to guarantee total compliance with regulations. Every glove or garment is certified according to European and international regulations.

An example?

Soft and comfortable, in inherent flame retardant fabric, it is designed for all operators in the foundry industry, where the risk of contact with molten metal splashes is high. All according to EN ISO 11612:2015 standard A1 B1 C1 D3 E3 F1.

Find an in-depth look at the most risky roles in the land industry on our blog.

Also for heat-resistant products, we offer high-end, fully certified PPE, such as the V2KA aramid fibre coat.

It protects against accidental contact with flames, but above all is suitable for protection against radiant heat thanks to the thermo-reflective properties of the aluminised fabric.

It also provides excellent protection against aluminium and molten iron splashes.

Read more about our aluminised PPE and how to best protect yourself in our Safety Magazine article.

Don’t take any risks and contact us to learn more and for proper advice in choosing your PPE.